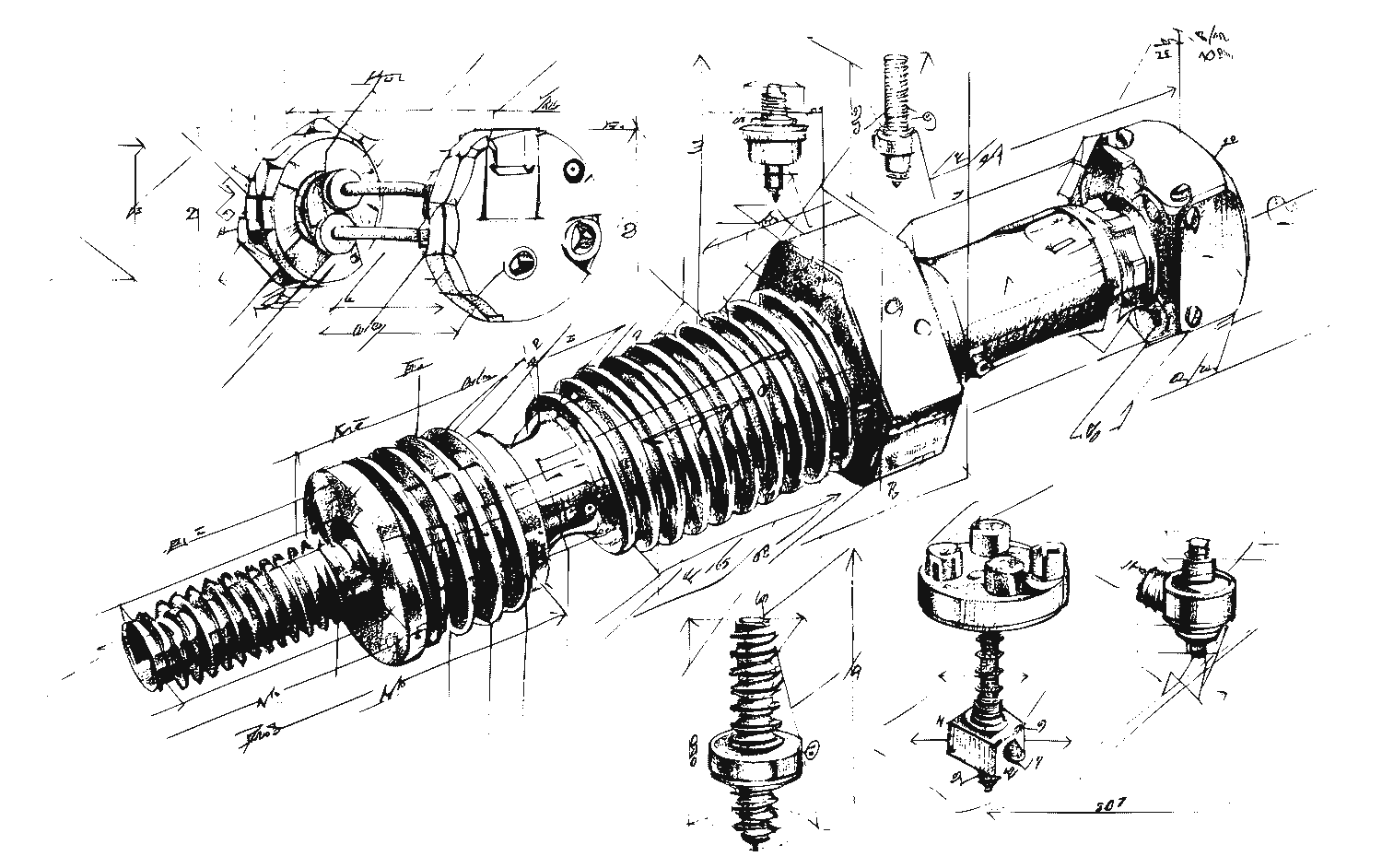

Italian passion for

precision mechanics

BUSINESS VISION

Swiss Precision, Italian Flexibility

We bring the excellence of Swiss precision mechanics to Valchiavenna in Northen Italy, maintaining great attention to detail to offer innovative and reliable solutions to every customer.

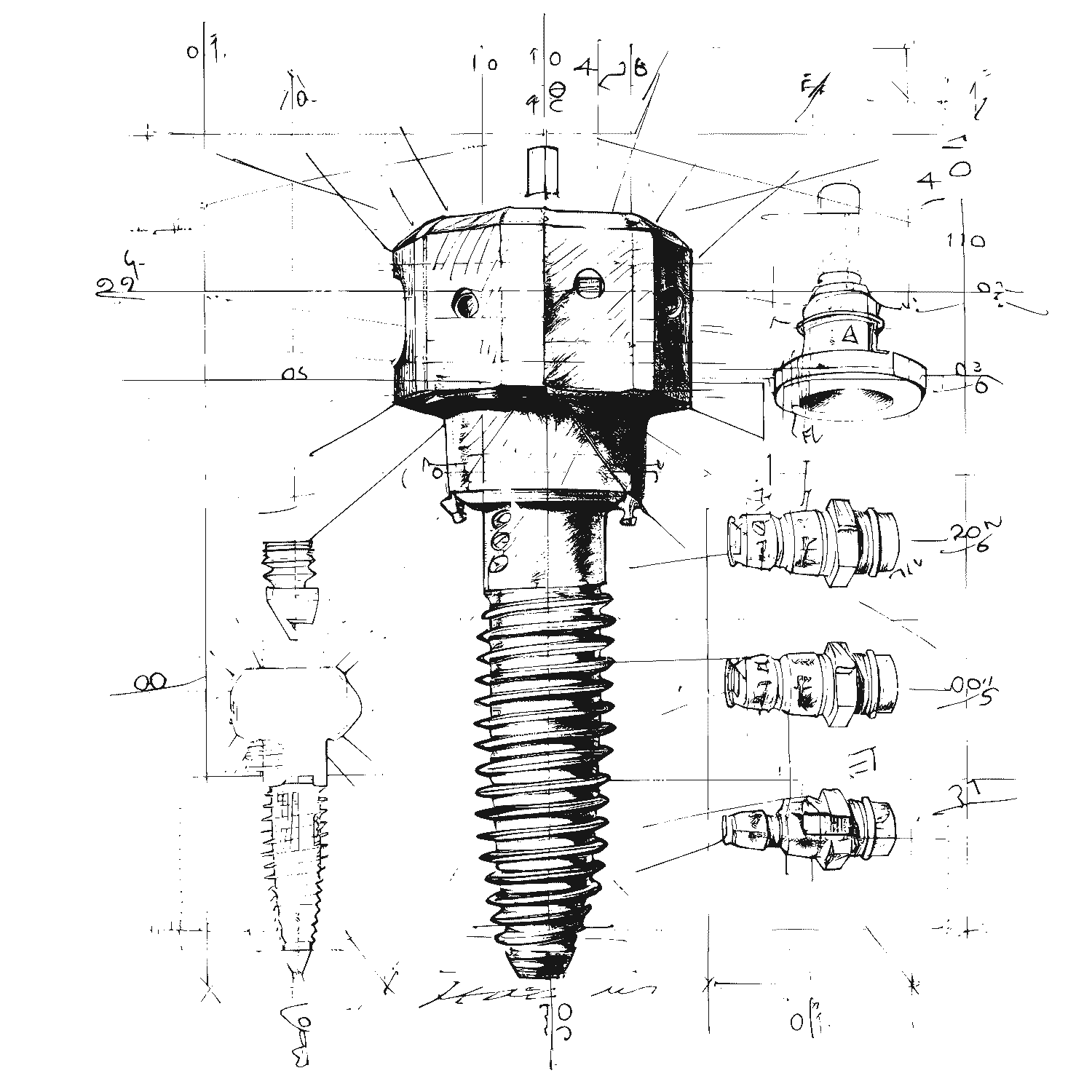

Scientific Method and Instinct

Every project is born from a balance between rigorous analysis and creativity. We combine the scientific method for precision and reliability with instinct and experience to create unique and tailored solutions.

Beauty Lies in the Details

We define this dedication as “Italian spirit,” but many call it “Made in Italy“. From this spirit comes the idea of our logo, which recalls the Italian tricolour… because we believe that also mechanics is a form of art!

Fields of Work

mBm aims to grow internationally, specializing in niches that require precise tolerances and prototyping, such as:

- Medical

- Veterinary Medical

- Micro Mechanics

- Electronics

- Fine Mechanics

- Energy

mBm aims to grow internationally, specializing in niches that require precise tolerances and prototyping.

Processes

The goal of mBm is to design equipment and products that solve process problems for other companies. Our experience includes:

- Traditional Machining

- CNC Machining

- Design

- Knowledge of production processes, from watch screws to underwater oil valves

The goal of mBm is to design equipment and products that solve process problems for other companies or for ourselves.

Certifications

Certifications in the process of being obtained, including ISO 13485, demonstrating our ongoing commitment to quality management.

AREAS OF EXPERTISE

MACHINERY AND MEASURING INSTRUMENTS

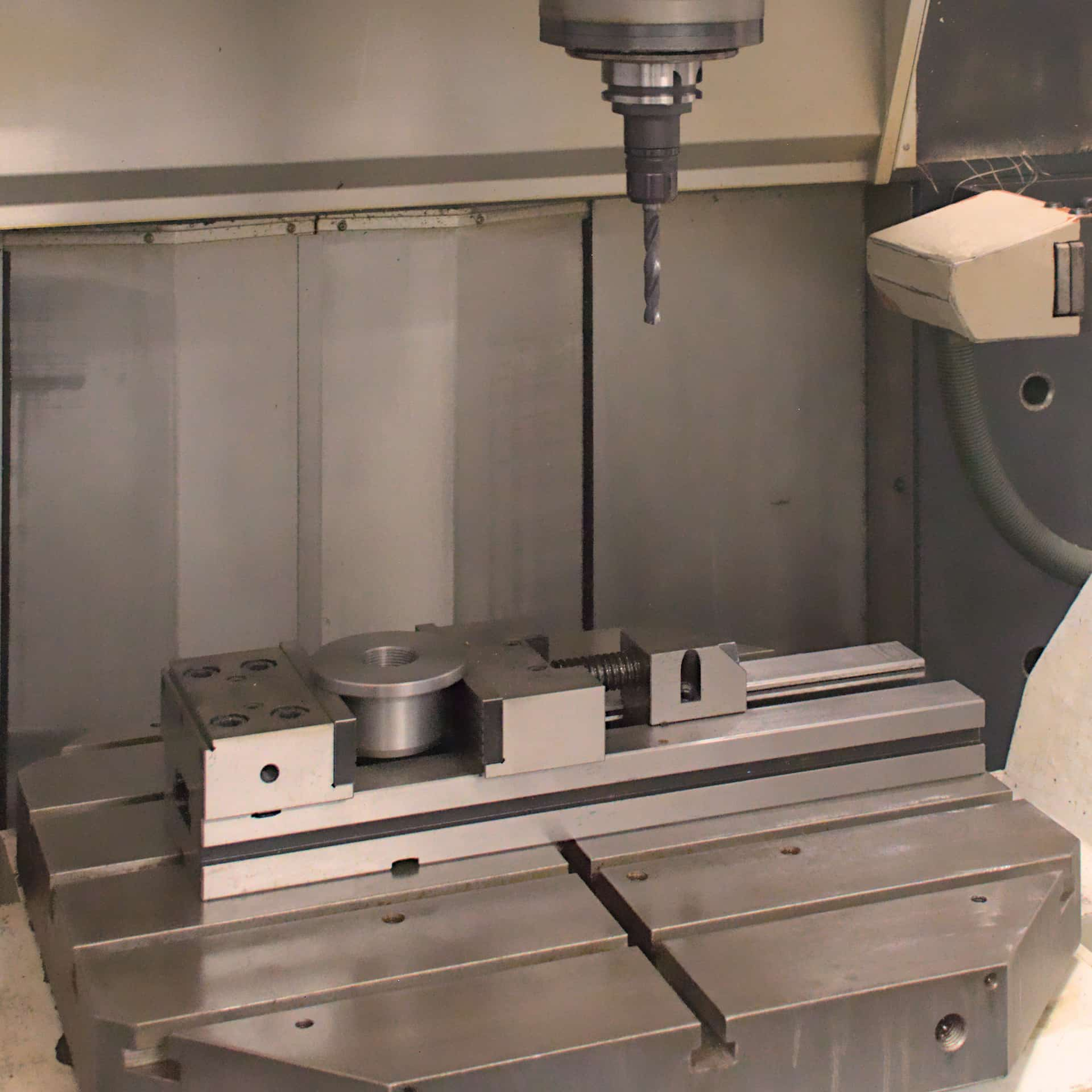

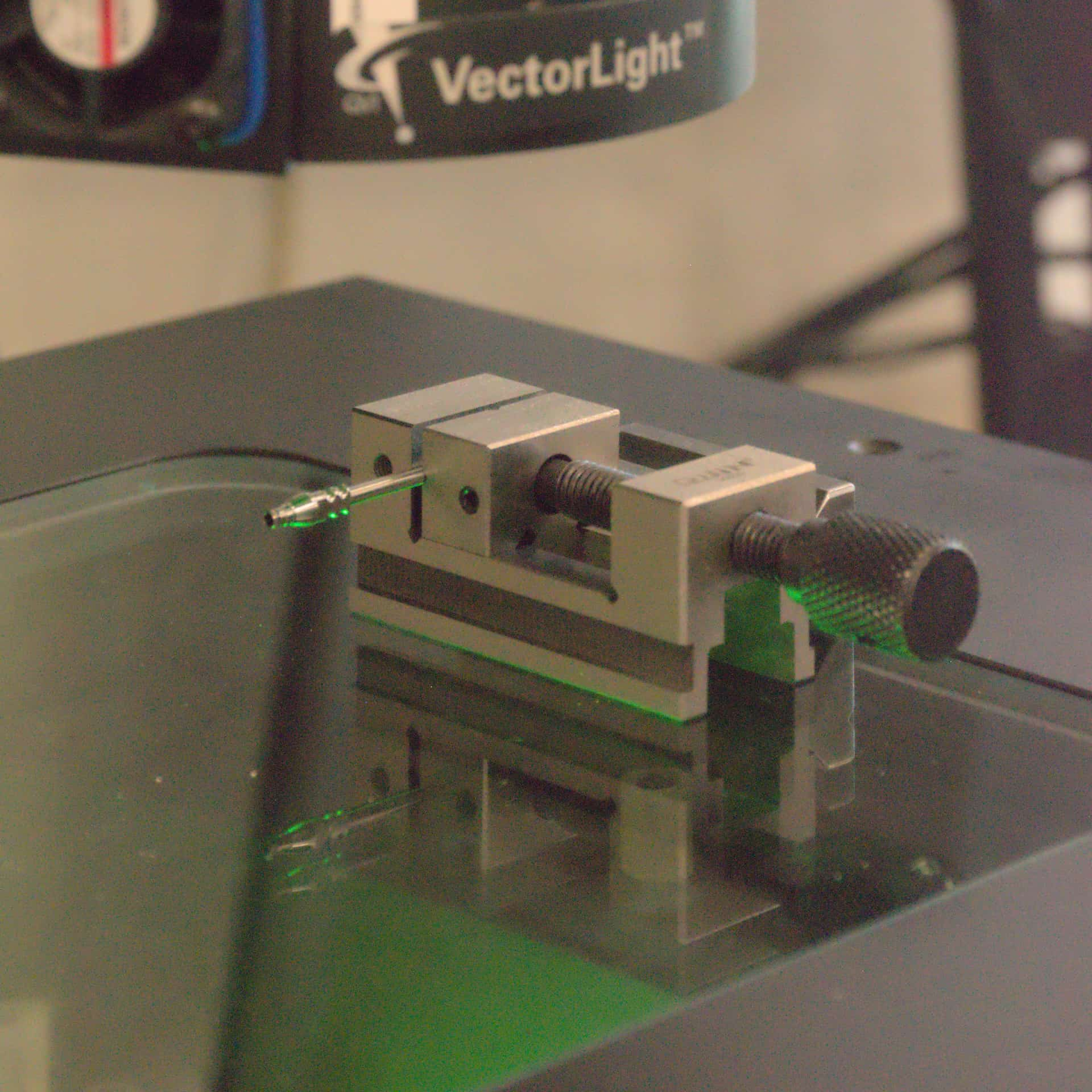

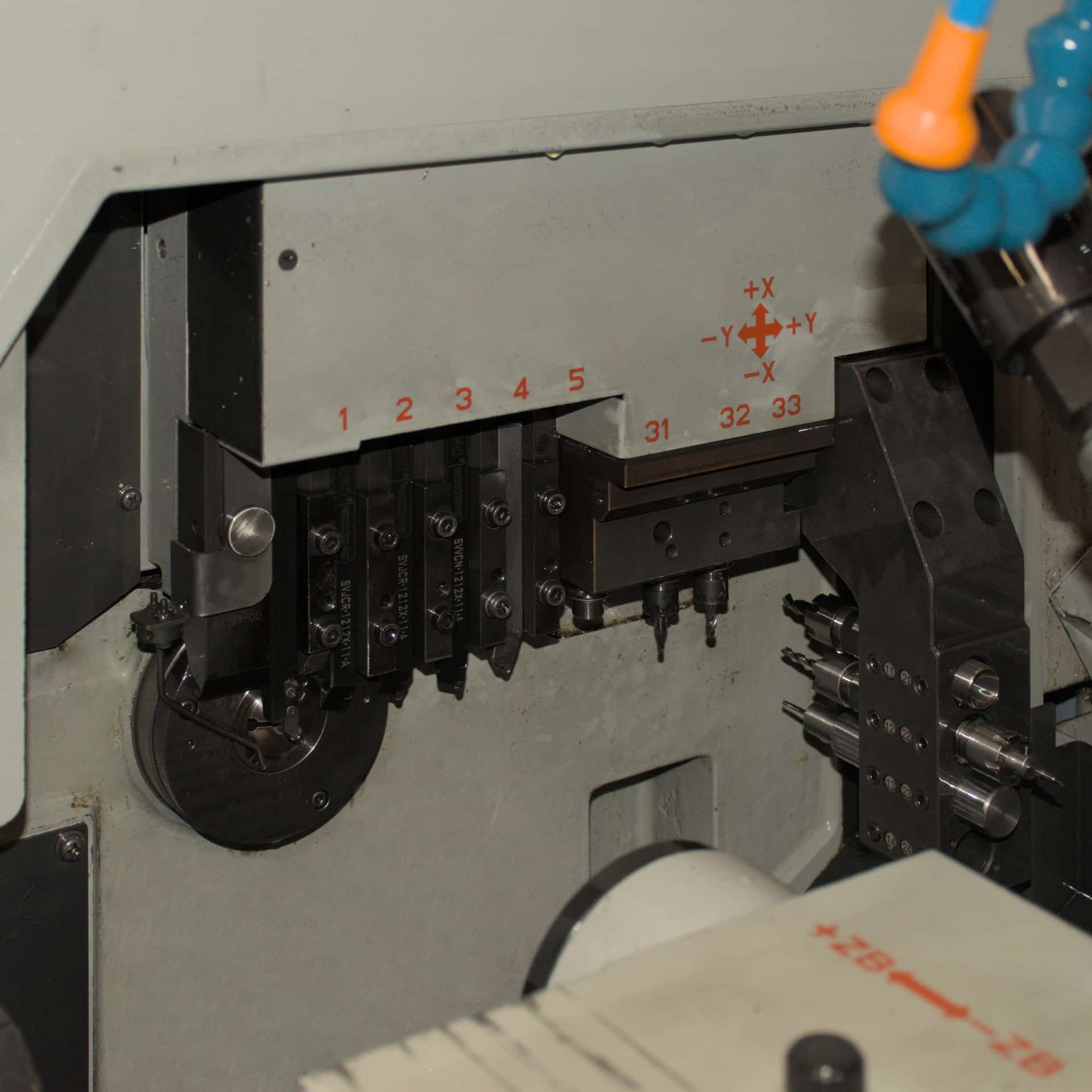

Personal photos of the machines and instruments available.

MECHANICS FOR DEMANDING INDUSTRIES

From Raw Material to Finished Product, with Precision.

Selected Raw Materials

We use certified and traceable materials, such as stainless steels, titanium, and light alloys, chosen based on application needs.

CNC Machining

Production with sliding headstock lathes and 5-axis milling machines. Processes are managed internally, from programming to final inspection.

Quality Control

Each phase is monitored with contact and optical measuring instruments. Tolerances meet the required specifications, even in the most critical fields.

Industries Served

Components for medical devices, fine mechanics, electronics, and the energy sector. Customised batches upon request.

Production Cycle Management

From the first contact to delivery, the flow is controlled internally thanks to the use of the Metronomo management software, which allows organising, analysing, and tracking every production aspect.

Safety and Environment

Low-impact processes: use of vegetable lubricants, no external emissions, protected work environments.

Let’s Have a Coffee!

Every project starts from a concrete need. Tell us yours: we are here to listen and build a tailored technical solution.